Aerogel provides ultra-thin, high-performance thermal insulation for buildings, including new constructions, renovations, and historic structures, reducing energy consumption while saving interior space and offering excellent fire resistance. In industrial and energy applications, aerogel insulates pipelines, boilers, storage tanks, and energy storage systems across a wide temperature range, including cryogenic conditions, enhancing thermal stability, safety, and operational efficiency. Its lightweight, high-porosity structure makes it ideal for aerospace and extreme environment applications, protecting spacecraft, satellites, and high-altitude vehicles from severe temperature fluctuations. Additionally, aerogel delivers compact thermal management solutions for electronics, electric vehicle batteries, and renewable energy systems, improving performance and energy efficiency without increasing bulk.

Advantages & Why Use Aerogel

1.Among insulation materials, aerogel achieves one of the lowest thermal conductivities (e.g. ~0.013 W/(m·K) under some conditions), meaning much thinner insulation layers can match or outperform traditional bulky insulation.

2. Aerogel’s porous, air‑filled structure gives very low density and high insulation per thickness, enabling lightweight, space‑efficient solutions.

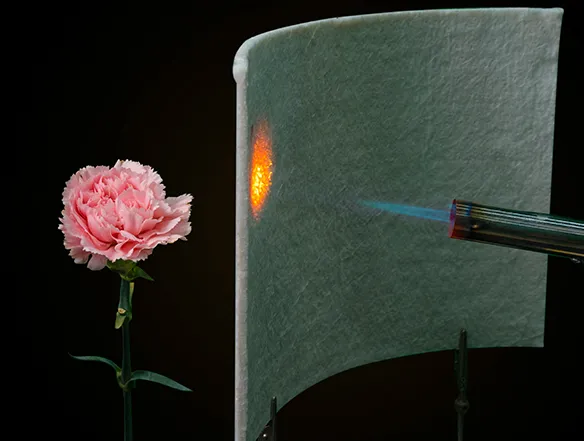

3. Applicable from cryogenic temperatures up to high industrial temperatures; certain aerogel types are non‑flammable or fire‑resistant, improving safety in building or industrial environments.

4. From building insulation to aerospace, energy, cryogenics, electronics, industrial equipment — aerogel’s properties make it useful in many sectors.

5. Aerogel works with thin layers and low weight, it’s ideal for retrofit scenarios, weight‑sensitive applications (e.g. aerospace), or compact designs (electronics, energy modules).

In terms of business scope, it covers general items: sales of aerogel products, building materials, building decoration materials.